15 technical challenges to consider and conquer when designing a 48V power delivery network

To help better prepare for your 48V migration, consider the following 15 challenges as you embark on your first 48V designs

Density of power components has increased several orders of magnitude over the past couple of decades. On one hand this has led to a significant reduction in size and cost of power electronic converters; on the other hand, designing the appropriate cooling solution has become more and more challenging. In many cases, thermal management is the gating item that determines the feasibility of a project, and the thermal management solutions need to be evaluated at a very early stage in the design of a power supply.

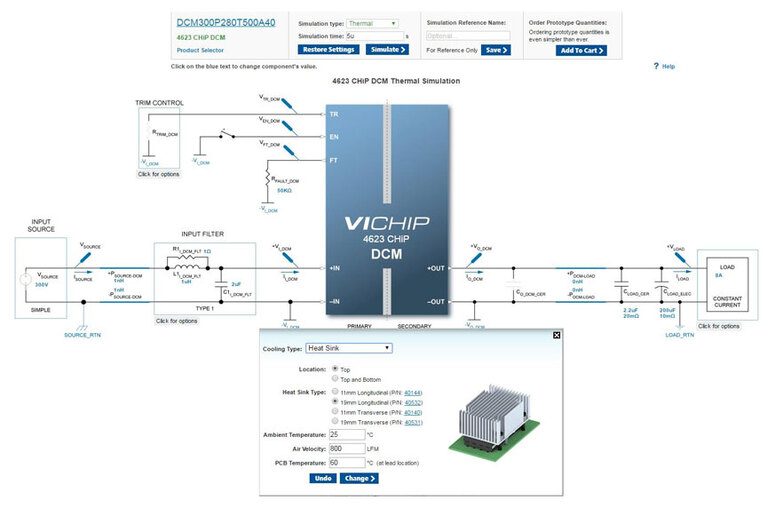

To simplify your thermal evaluation Vicor has released several simulation models that enable evaluation of the thermal characteristics of our products. The simulator allows you to do a preliminary evaluation of the functionality of our products in your specific environment and operating conditions. The simulator evaluates whether the operating conditions selected by the user when under the selected cooling option are within specification, or if modification to the selected cooling strategy are needed.Overview of Vicor thermal simulator interface. In this example, the cooling type selected was “Heat Sink”. The Option of a “User Defined Cold Plate” is also available.

With just a few clicks, you can select the Vicor power component you are planning to use, customize your source and load conditions, ambient temperature, and evaluate the feasibility under several possible choices of cooling solutions. These solutions may include various types of Vicor heatsinks, as well as custom defined cold plate solutions. In a few seconds you will be able to determine the ideal cooling approach for your project, and you can proceed with your design knowing that thermal management has been addressed already!

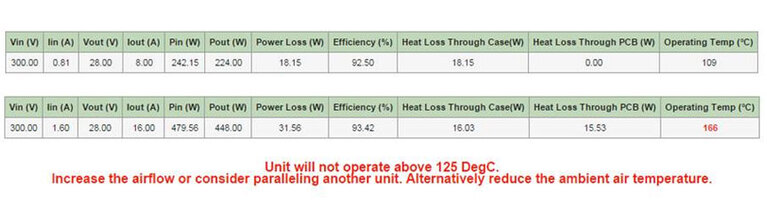

Figure 2: Examples of results returned by the thermal simulation: the top image shows a cooling solution that is adequate for the selected operating conditions; the bottom one shows a cooling solution that is undersized, and provides directions on how to improve the thermal management.

15 technical challenges to consider and conquer when designing a 48V power delivery network

To help better prepare for your 48V migration, consider the following 15 challenges as you embark on your first 48V designs

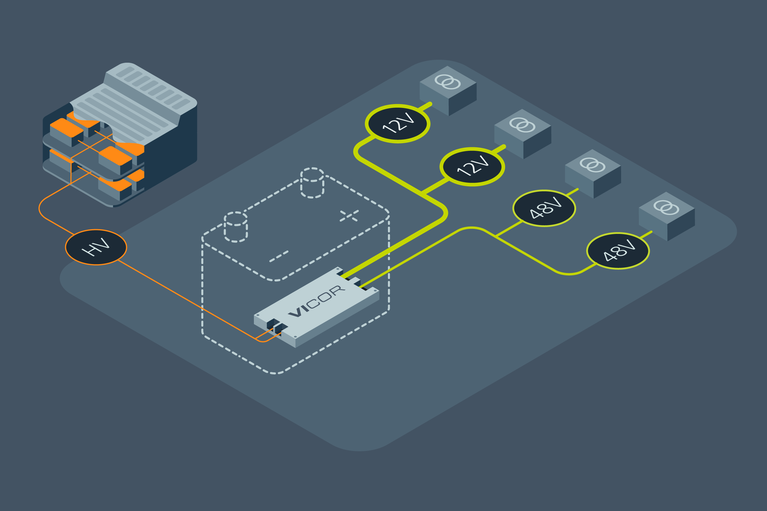

Future-proof automotive high-voltage-to-SELV conversion

Legacy 12V architecture is no longer capable of sustaining the rising electronic loads in automobiles. Learn how power modules hasten the transition to 48V

電源模組助力簡化電動汽車的爬電距離與電氣間隙設計

包覆成型(Overmolding)是解决48V汽車電源系統中電弧問題的關鍵

壓力下的動力:滿足軍事領域激增的電力需求

軍事電源系統設計者需要更多的效能(功率)和兼容性。 瞭解 Vicor SOSA 電源如何解决難題