Accelerate your move to a high performance 48V power delivery network

This eBook provides guidance on designing 48V power delivery networks to enhance the performance, efficiency, and reliability of industrial products

Gain some valuable technical insight into Vicor Power solutions by reviewing these frequently asked questions taken from actual customer engagements.

By Matt Renola, Sr. Director Global Sales Aerospace and Defense

Since it’s inception in 1981, Vicor has a long heritage of serving customers in the aerospace and defense markets. Vicor has long supported key engagements in air, ground and shipboard power applications. Vicor high-performance MIL-COTS power modules offer high density and efficiency with reliable and robust designs backed by 30‑years of dedicated excellence in the aerospace and defense industry. Using that knowledge base we have compiled a list of commonly asked questions we feel will provide some guidance and insights along your power design journey.

Military ground vehicles present various challenges when designing and meeting power requirements. Power supplies need to withstand shock and vibe requirements associated with rough terrain. Dust, humidity or sandy conditions are also present in these types of applications. Cranking voltages during vehicle start-up pull a tremendous amount of current and lower input voltage ranges. This all needs to be accounted for when deciding if your critical electronic equipment needs to ride through start up. Vicor has a long history in supporting military ground verhicle designs and can direct you to a host of standard products that meet Mil-STD-1275 requirements. MIL-STD-1275 power supply standards outline all the requirements that an engineer needs to account for when designing his/her power supply. Military vehicles distribute a nominal 28VDC bus voltage for opportuning electronic systems. According to MIL-STD-1275, ground vehicle power supplies must be able to handle transient spikes of up to +/– 250VDC for 50 micro seconds for 1msec. Vehicle surge requirements of up to 100VDC for 50msec. must be met without affecting the regulated output.

The Vicor 28V DCM™ DC-DC Converter Modules have input ranges from 9 – 50VDC in order to address low cranking voltage and surges of up to 50VDC without affecting output regulation to your critical electronic needs. Vicor also provides MFM™ DCM filters for meeting MIL-STD-1275A/B/D/E requirements. These DC front-end modules provide EMI filtering and transient protection when used in conjunction with the Vicor 28V nominal input voltage VIA™ or ChiP™ modules.

Vicor has design centers in North America that support build to spec or build to print system designs. These entities can customize solutions based on your statement of work (SOW). Having the Vicor highly engineered components already designed allows for quick response to provide full turn-key solutions. Vicor has many years of experience and has the design engineers and applications expertise to assist you with designing your mission critical needs.

Every module undergoes extensive post-production environmental stress screening (ESS) before shipment to verify compliance with Vicor high-quality and performance standards and to eliminate early life failures. To ensure the most effective routine for precipitating module failures, Vicor continually evaluates its ESS program and makes appropriate changes as new data becomes available or as product improvements occur. After burn-in and temperature cycling, each module undergoes final electrical testing over the specified temperature range.

When a single wide-input-range DC-DC converter results in unacceptable performance and cost, a combination of two or more DC-DC converters with overlapping input voltage ranges may be an effective alternative. Combinations of DC-DC converters with narrower but complementary input voltage ranges will typically operate at higher efficiencies and higher power densities allowing the total design to be smaller, more efficient and less costly than a single-converter solution. In applications that require ultra-wide-voltage input ranges, using a single DC-DC converter often forces a power system designer to accept significant reductions in available power, power density and system efficiency, while increasing overall system cost. Leveraging the efficiency, power density, ease-of-use and wide variety of Vicor DCM DC-DC converters, it is possible to create a smaller, more efficient and potentially less costly solutions for military applications.

One example of advanced packaging that improves power processing and delivery performance is the Converter housed in Package™ (ChiP) technology from Vicor. ChiP-based devices exploit symmetrical configurations placing dissipative devices on both sides of a central PCB. A thermally conductive encapsulant transfers heat to both the top and bottom surfaces effectively doubling the cooling surface area relative to the device’s PCB footprint. The module’s encapsulant allows the module to meet shock and vibration standards.

When mounting to module to a pcb the designer has to consider the module a part of a system. The system typically uses standoffs and other mechanics to meet shock and vibration standards.

Because our products are compact and designed with thermally-adept packaging, most are ideally suited for many MIL applications, including surveillance, communications, radar and pulsed load. Vicor has a range of 270VDC, 28VDC and 48VDC input products. A power module design approach easily addresses challenges presented by load capacity, placement and user functionality requirements. To support easy power design development, Vicor offers an online tool, the Power System Designer, to aid in selecting the appropriate product(s) to optimize your power delivery network.

Yes, we offer valuable tools online for simulations and assistance using thermal management and component calculators. In addition, we are offer demo boards and our applications engineers are available to assist with design reviews.

So, as significant an advance as brick packaging technologies were, and while the brick form factors still play a role in terms of simplicity, the industry has grown to need even more dense power management devices beyond what can be accomplished with purely single-sided cooling.

One example of advanced packaging that improves power processing and delivery performance is the Converter housed in Package (ChiP) technology from Vicor. ChiP-based devices exploit symmetrical configurations placing dissipative devices on both sides of a central PCB. A thermally conductive encapsulant transfers heat to both the top and bottom surfaces effectively doubling the cooling surface area relative to the device’s PCB footprint.

Vicor has established a power module capability spanning product design, manufacturing, simulation and selection tools. This capability allows Vicor to enable power systems designers to quickly and easily deploy high-performance power delivery networks (PDNs), from the power source to the point-of-load (PoL) for end systems extending across many different industries such as (defense and aerospace, LED lighting, etc.).

This modular power component approach signifies a new standard within the power industry, addressing the increasing power needs of modern, high-performance end systems with a methodology that also provides other power system benefits such as reduced power system footprint, high efficiency and faster time to market.

Power delivery networks are rapidly changing within many end systems across many industries today. The power requirements for these different systems vary widely from each other and require a wide portfolio of modules to enable the maximum flexibility for a modular power component methodology to be employed. The range of modular power solutions Vicor provides include:

In addition to the above, there are also different control features such as telemetry, compensation and programmability, plus any industry/safety certifications that can be required.

Leveraging the benefits of our DC-DC converter technology and modular building blocks, Vicor offers a range of standard and modified-standard VPX power systems for use in compact enclosures and space-constrained airborne and vehicle environments where temperature, shock and vibration conditions can be severe. There are 3U and 6U models available which are compliant to the VITA 62 standard, along with SOSA aligned models. The current products are available 3-phase AC in, 270VIN, and 28Vin, and are capable of providing one to six user-configurable outputs, with voltages from 2VDC to 48VDC. Standard features such as wide output trimming / programming, current limiting, remote sense, reverse polarity protection, logic enable / disable are available. Products meet relevant standards, including MIL-STD-810F environments, MIL-STD-461E EMI, MIL-STD-1275A B and D, MIL‑STD-704D/E/F transient compliance and MIL-STD-1399A, shock and vibration in conformance with MIL-STD-901D.

Matt Renola is Senior Director, Global Business Development – Aerospace, Defense and Satellite Business Unit at Vicor. Matt has been with Vicor for 15 years and has been responsible for managing the Vicor sales teams and global accounts in all of Vicor main vertical markets. He has over 30 years of technical sales and marketing experience and has also worked for major OEMs: Artesyn Technologies, Emerson Network Power and Vishay Intertechnology. He has an undergraduate degree from Boston College and an MSE from the University of Pennsylvania.

By Matt Renola, Sr. Director Global Sales Aerospace and Defense

Rugged, efficient, high-power solutions enabling longer missions and advanced defense capabilities

Case study: Aircraft gets an 11kW power supply the size of a tablet computer

Article: Defense-electronics spending seeks to overcome COVID-19 setbacks in key applications

Modules for aerospace and defense applications

Accelerate your move to a high performance 48V power delivery network

This eBook provides guidance on designing 48V power delivery networks to enhance the performance, efficiency, and reliability of industrial products

Build better UAVs using modular power

Power Delivery Networks (PDN) based on Vicor high performance power modules enable innovative designs for the next generation of UAV development

High-density, high-power modules enable lighter, safer, lower cost tether cables to extend missions

This class of unmanned vehicle is powered and controlled via a tether from a ground-based power source assisting in extended missions

High-efficiency, high-density modules free up space for advanced communications and extend range

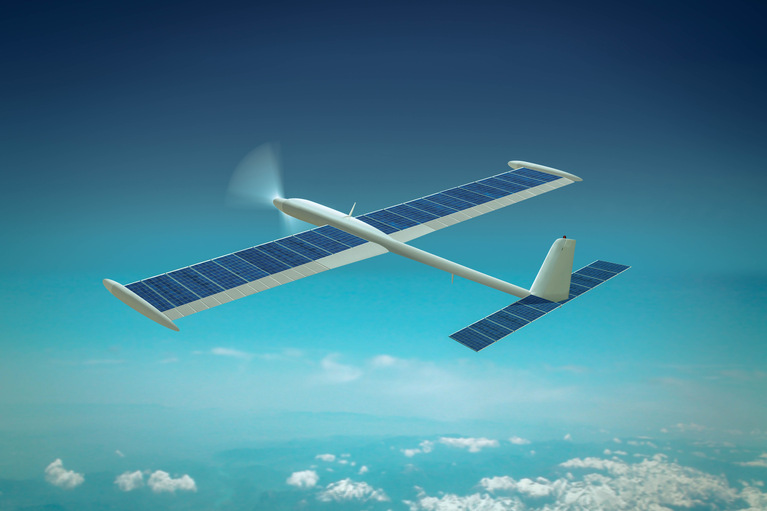

High-efficiency class of UAV depend on solar power to meet its long flight time requirements