Accelerate your move to a high performance 48V power delivery network

This eBook provides guidance on designing 48V power delivery networks to enhance the performance, efficiency, and reliability of industrial products

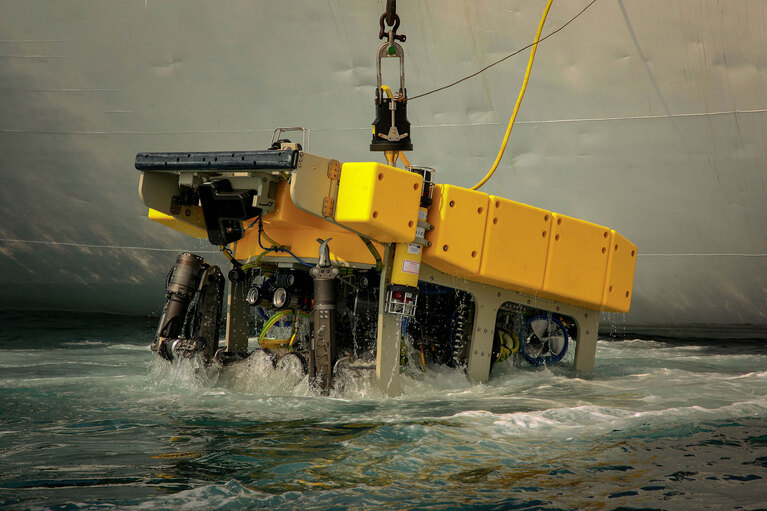

Case study: Tethered Underwater ROV

Allowing an underwater ROV to perform remote inspection activities at greater depths required the tether from the ship-based power source be extended. Distributing the original design’s low voltage over the longer tether was not practical due to voltage drops. Moving to a high-voltage 700V low-loss tether, however, required conversion to a lower SELV voltage onboard the ROV. This typically requires a custom converter that takes up space and adds weight, not feasible in an ROV that needs to be able to carry increased payloads. The key goals were:

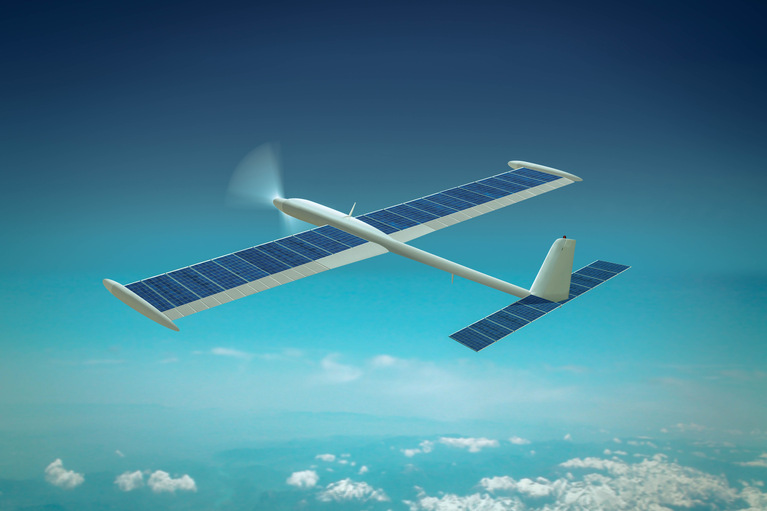

Vicor high-efficiency and high-performance power modules enable inspection UAVs to minimize size and weight to maximize the sensor payload required to perform the actual inspection. With enough power and high efficiency, they allow for an agile UAV with increased flight time, even in harsh environments.

High-voltage tether reduced the supply current, and thus losses for a given cross-section of copper conductor, allowing for a thinner, longer tether

Reduced footprint of 1.5kW solution to just 41cm2

Low noise conversion topology prevented interference with communications over the tether

The power delivery network: The BCM isolated and stepped-down the high tether voltage input to a nominal 48V, a factor of 1/16. Output was 1.5kW in a footprint of just 39cm2. The BCM provided enough power to drive 48V motors, thrusters and control electronics. Its high efficiency simplified the cooling within the vehicle. ZVS Buck regulators converted the 48V SELV distribution to 5V and 3.3V to power downstream points-of-load. To analyze this power chain, go to the Vicor Whiteboard online tool.

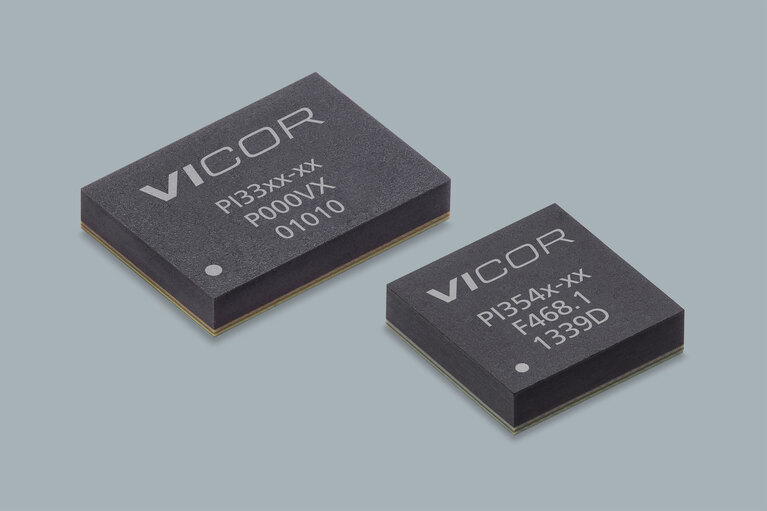

絶縁 電圧変換比固定

入力電圧: 800 – 48V

出力電圧: 2.4 – 55.0V

出力電流: 最大150A

ピーク効率: 98%

22.0 x 16.5 x 6.7mm 他

非絶縁 レギュレータ

入力電圧: 12V (8 – 18V), 24V (8 – 42V), 48V (30 – 60V)

出力電圧: 2.2-16V

出力電流: 最大22A

ピーク効率: 98%

10.0 x 10.0 x 2.56mm 他

Accelerate your move to a high performance 48V power delivery network

This eBook provides guidance on designing 48V power delivery networks to enhance the performance, efficiency, and reliability of industrial products

Build better UAVs using modular power

Power Delivery Networks (PDN) based on Vicor high performance power modules enable innovative designs for the next generation of UAV development

High-density, high-power modules enable lighter, safer, lower cost tether cables to extend missions

This class of unmanned vehicle is powered and controlled via a tether from a ground-based power source assisting in extended missions

High-efficiency, high-density modules free up space for advanced communications and extend range

High-efficiency class of UAV depend on solar power to meet its long flight time requirements