Future-proof automotive high-voltage-to-SELV conversion

Legacy 12V architecture is no longer capable of sustaining the rising electronic loads in automobiles. Learn how power modules hasten the transition to 48V

Electric vehicles have a weight problem. Here’s how enhancing converter power density and flexibility can deliver more range and faster charging.

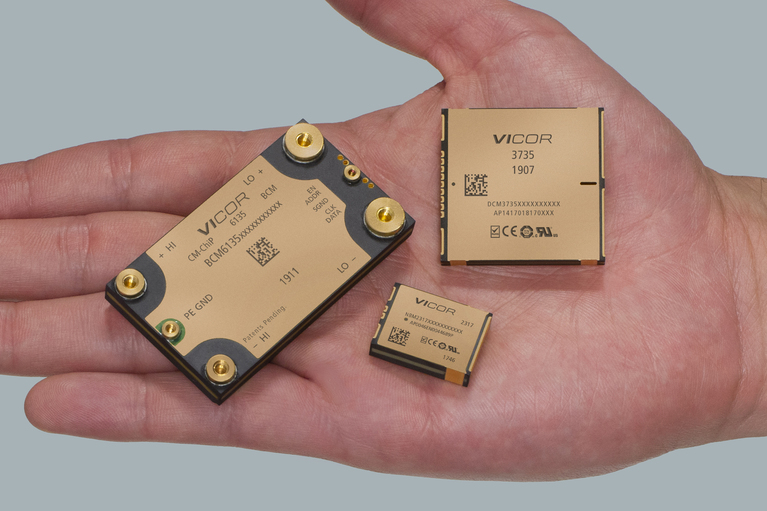

Based in Andover, Massachusetts, Vicor has been developing and manufacturing high performance power modules for crucial industries since 1981, from communications and computing to defence and robotics. Over the last six years, the company has branched into the transport industry as it undergoes an era of electrification to deliver compact, power-dense DC-DC power conversion devices to aid the transition to electric vehicles (EVs).

“If you’ve been following automotive, you will know that EVs have a weight problem,” explains Greg Green, Director of Automotive Marketing at Vicor. “They’re heavier than standard vehicles by 15-33%, which causes a number of issues. So, there is a lot of work ongoing in the automotive segment to lighten the cars. The other thing is that adoption has plateaued for several reasons. One of these reasons is that consumers looking to adopt EVs are really looking for about a 540km range, and the average right now is around 100km or so short of that. So, that’s causing people to second guess whether they are ready to switch to an EV or not.”

However, reducing the weight of an EV is not an easy thing, as Green concedes. “There are several approaches to taking the weight out of a vehicle: Downsizing or lightweighting the battery pack, eliminating low voltage batteries and downsizing DC-DC converters. Since the mid-sixties, the automotive world has been a 12V world. However, 48V is of interest because electrically you have to get under 60V to be considered safe, but it also gives you room to go over or under voltage. The Tesla Cybertruck was rolled out as the first to have a large amount of 48V power systems in it, which got everyone excited, and since then we have seen a lot of movement in this area.”

Figure 1: The high-performance power modules

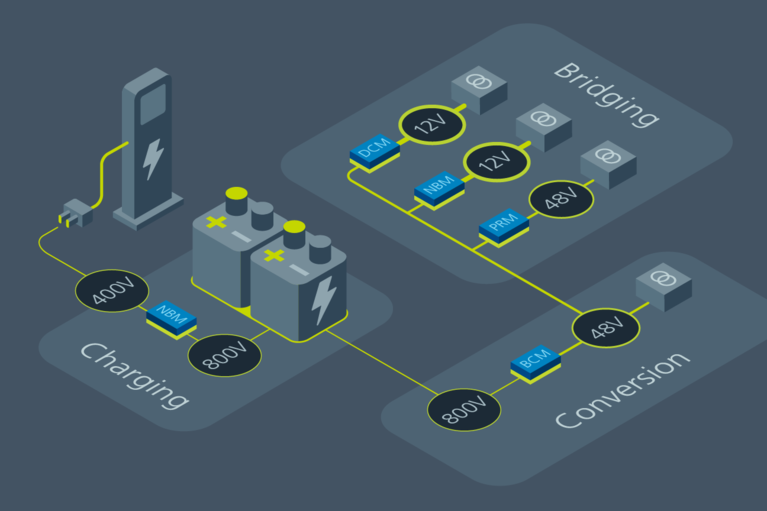

To address these challenges, Vicor has identified several key areas where its technology can have a significant impact. Through its highly power-dense conversion devices, the company is working to enable downsizing of the battery pack, eliminating low voltage batteries, downsizing the DC-DC converters, integrating smaller DC-DC into the battery housing, and introducing 48V zonal architecture.

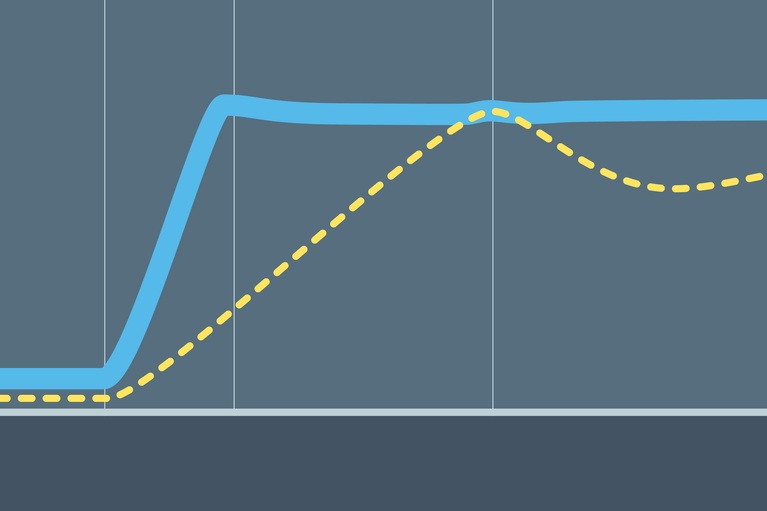

“We use a process of power conversion called zero-voltage switching, which is very fast,” Green explains. “This means we can go from zero power to full power at a rate of eight million A/s, taking power from the high voltage battery and converting it to 48V and running it to a load faster than if you had a standard 48V or 12V battery feeding that load. This is important because there’s no lag, which allows you to get rid of the low voltage battery or drastically downsize it, and this can take about 10kg of weight out of a vehicle.”

The other aspect Vicor focuses on is downsizing the DC-DC converter. “We take 3-5l systems and downsize them to 1 – 1.5l of space,” Green adds. “In passenger cars in particular, space is critical, but even with larger vehicles, using less space gives you more flexibility in the layout design of the vehicle and can bring other efficiencies. As a demonstration, we looked at the Tesla Model X, which has one of the best power-to-weight and power-to-volume ratios, and Vitesco’s new fourth generation system. We found that our system would be two to three times better than both of those in terms of its efficiency and its power-to-weight and power-to-density. Our system brings the DC-DC converter down to a size that an engineer can comfortably imagine putting inside a battery housing.”

Essentially, Vicor’s approach enables the DC-DC converter to be downsized and tucked away in one of the corners of the battery housing, which saves weight through removing the need for a metal housing around it and makes use of the existing cooling system in the housing to cool the electronics. From a safety perspective, the approach also reduces the number of high-voltage power cables coming out of the battery housing.

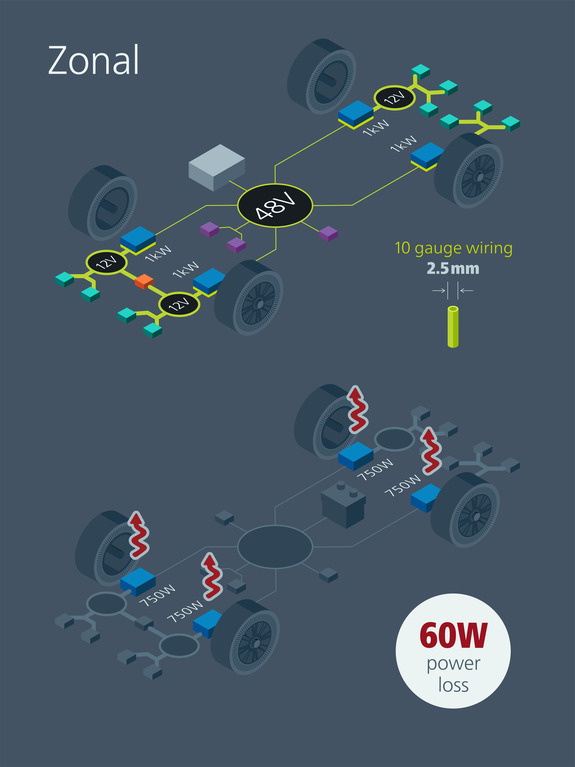

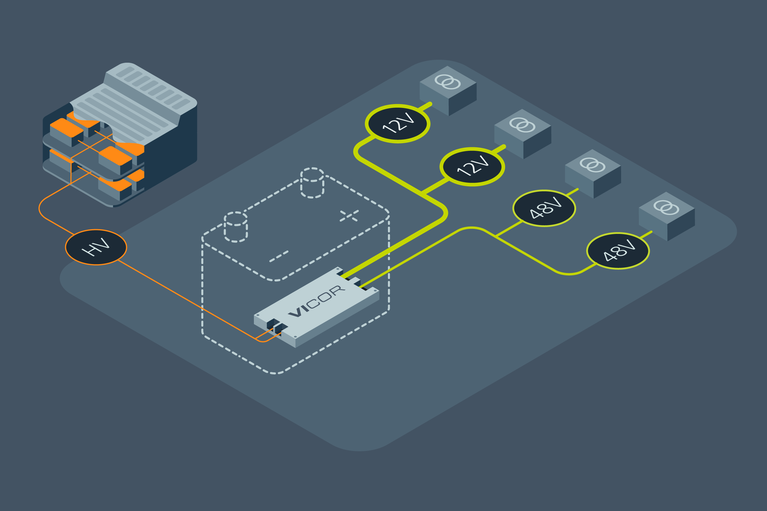

Figure 2: 48V zonal architecture

As Green explains, 48V zonal architecture was first discussed in the late 1990s with the emergence of the first hybrid EVs as a potential path to maximizing thermal efficiency. However, the technology had not seen much development until Tesla brought out the Cybertruck last October.

“The reason for this is that the majority of alternators are 12V or 24V,” says Green. “The engineering and testing costs to change those alternators was quite steep, and so there was resistance to it. But, if you go to plug in an EV or hybrid vehicle, you automatically have a high voltage battery. When you think of it from a system perspective, it’s easier to conceive that we should be running 48V coming off the high voltage. 48V wires are about 10% of the diameter and weight of a 12V wire, and voltage kind of equates to pressure: low pressure means you need bigger pipes, high pressure means you can use smaller pipes. So, 48V is higher voltage, and higher pressure. You can use smaller wires which weigh less, and which also use far less copper than a 12V wire. And then, thermal losses are also dealt with more efficiently with a 48V design as you’re able to run the 48V to multiple points in the vehicle and locally convert it to 12V power needed across the vehicle. This drives benefits for weight and cooling complexity throughout the whole EV.”

Figure 3: Thermal losses are dealt with more efficiently with 48V design

When you add all these elements together – removing the low voltage battery, downsizing the DC-DC converter and introducing 48V zonal architecture in the wiring – Vicor calculated engineers could save around 18kg of weight per vehicle.

“That is a really substantial saving in an industry that generally fights over single grams,” Green says. “But what does this really mean for people who operate the vehicle? Well, we figured out that if you reduce the weight of a vehicle by 18kg, you can add 1 – 2.5km of range, which doesn’t seem like a lot. But, if you could then add 18kg of battery cells due to that saving, you would increase the range by 5%. This lifts us much closer to that sweet spot that consumers are looking for to make the leap to adopting EVs at passenger car level. The same thing would be true for larger vehicles, in fact the argument may even be stronger in commercial vehicles where saving 18kg could mean you can haul 18kg more in cargo or passengers.”

With this in mind, it’s clear that Vicor’s higher power density DC-DC converter modules have the potential to provide both flexibility and efficiency into the power delivery network, supporting integration into the battery due to their smaller size and reduced heat emissions.

“EV manufacturers can take advantage of these benefits to reduce vehicle weight and move closer to the 540km range sweet spot that will ultimately help to speed up EV adoption,” Green concludes.

This article was originally published by Engineer Live.

Future-proof automotive high-voltage-to-SELV conversion

Legacy 12V architecture is no longer capable of sustaining the rising electronic loads in automobiles. Learn how power modules hasten the transition to 48V

Power modules simplify creepage and clearance design solutions for electric vehicles

Overmolding is the key to solving arcing issues in 48V automotive power systems

48Vのパルス電力により、車のフロントガラスの解氷を60秒で実現

ベターフロスト社は、パルス電力を活用することで、自動車のフロントガラスの解氷を60秒足らずで実現。Vicorの電源モジュールと48V電源イノベーションについて詳しくみる。

Bidirectional power and transient speed enable scalable active suspension

Sine Amplitude Converter™ modules offer a unique combination of bidirectionality and transient response to unlock new possibilities for active suspension