Optimizing DC-DC converter stability: AC and transient analysis in simulations of source impedance effects

Learn how to optimize DC-DC converter stability through AC analysis in the frequency-domain and transient analysis in the time-domain

A large film set emits the same CO₂ as the energy needed to power 650 US homes for a year (Time Magazine) using fossil fuel generators. ReVolt with the help of Vicor, has developed a portable DC-DC power system to power entire sets quietly and without any emissions. Now they are taking aim at other markets as well.

Gasoline and diesel generators have been powering Hollywood movie sets for years and emitting harmful carbon dioxide (CO2). Cameras, sound and lighting equipment, special effects rigs and basecamps all rely on generator power. As movie sets have grown in size and complexity, their carbon footprint has grown equally.

ReVolt provides clean, mobile, perpetual and quiet electricity with the ability to monitor power levels remotely via an app so mobile power stations can be recharged when needed. ReVolt leverages propriety technology and has incorporated small, power dense Vicor power modules to deliver scalable performance and portability to our fleet of power systems.

ReVolt’s systems eliminate the use of fossil fuels entirely. Each WeVolt unit prevents an average of 7.5 metric tons of CO2 per average sized film or television production and our Mules and CanaVans displace much larger diesel generators. Additionally, ReVolt systems produce zero particulate emissions and operate silently, removing local air and noise pollution that has long plagued film sets and construction sites.

Traditional diesel generators run at 85–95dB, making dialogue recording and crew communication difficult. Their systems need to be placed away from the set and require long cable runs. ReVolt units operate below 30dB, quieter than normal conversation. This allows for sound recording without generator interference, enabling production sound mixers to capture cleaner audio and reduce costly ADR sessions in post. The reduced noise also improves set safety and overall working conditions, while allowing night shoots in residential areas without disturbing communities — an important factor for city filming permits and sustainability compliance.

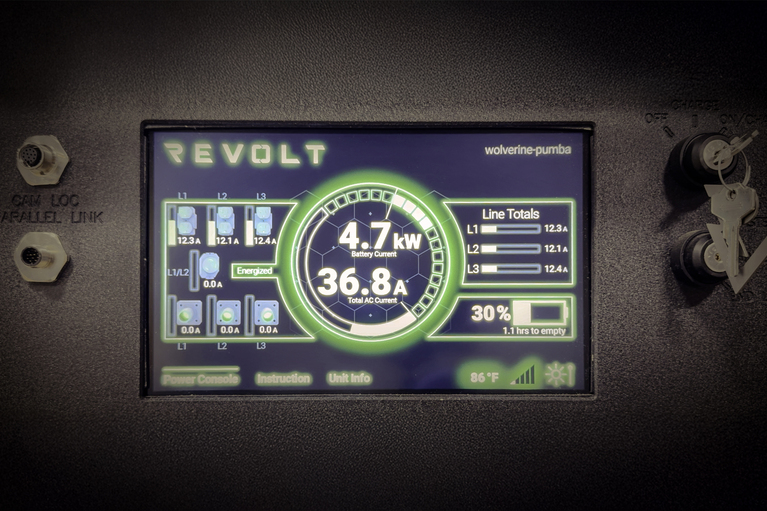

Our BMS monitors cell parameters. A group of parallel-connected, grid-forming inverters powered by a large DC battery pack (1) provides stabilized, utility-grade 3-phase output power to the loads. Another group of parallel-connected inverters, powered by a separate battery pack (2) with the same control features, shares the load and pushes additional energy into battery pack (1).

Each inverter monitors DC bus voltage and current, as well as 3-phase AC load characteristics such as voltage, current, phase angle and power factor. A separate modular power meter measures output voltage, current and phase angle for each leg, as well as neutral current. A custom-designed EMS controls and monitors each component via CAN bus, Modbus and Ethernet.

The smallest power system, the WeVolt, generates 17.5kWh capacity and 14kW output and the 8,500-pound Mule delivers 210kW of capacity and 120kW of output power, supplying on-demand energy across 480V, 208V, 240V and 110V connections. Additionally, this technology is virtually silent, emitting about as much noise as a computer fan.

We use 3-phase filter modules to protect against loads that generate harmonics. The system detects unbalanced 3-phase line connections, high neutral current and power factor issues, alerting operators in advance when parameters approach limits. Our EMS uses closed-loop voltage control, directing the inverters to adjust voltage based on load. This ensures no dips or spikes, managed through a fast PID control algorithm.

Our 800V DC bus is primarily kept close to the battery and only energises the charging infrastructure and inverter systems through BMS control and high-voltage DC contactors. We use a standardized low-voltage DC bus operating at 48V, 24V, 12V and 5V, supplied through Vicor modules. On the AC side, we start at 480V and step down via large transformers to 208V 3-phase, 240V split-phase and 120V single-phase.

WeVolt’s modular platform scales well beyond film and television. We’re actively expanding into construction, live events and emergency response — anywhere that requires high-reliability off-grid power.

This article was originally published by Electronics for Engineers.

Optimizing DC-DC converter stability: AC and transient analysis in simulations of source impedance effects

Learn how to optimize DC-DC converter stability through AC analysis in the frequency-domain and transient analysis in the time-domain

15 technical challenges to consider and conquer when designing a 48V power delivery network

To help better prepare for your 48V migration, consider the following 15 challenges as you embark on your first 48V designs

ReVolt – Technical Q&A

ReVolt is cleaning up Hollywood's emission problems today and next will address construction sites, emergency response and events with portable DC power

How ReVolt leverages Vicor technology for carbon-neutral film production

Vicor’s power converters to provide clean, mobile, and always-on electricity