Optimizing DC-DC converter stability: AC and transient analysis in simulations of source impedance effects

Learn how to optimize DC-DC converter stability through AC analysis in the frequency-domain and transient analysis in the time-domain

For more than four decades, Patrizio Vinciarelli has been blazing new paths in the power electronics industry, creating modular power components with industry-leading power and current density, for customers’ power systems.

Most people are aware of Gordon Moore, the legendary co-founder of Intel who famously observed back in 1965 that the number of transistors in a dense integrated circuit (computer chip) doubles about every two years. That cycle remains today, though it is approaching the limit of how engineers can manipulate matter at near quantum levels.

Far fewer people are aware of the similar cycle of innovation needed to convert an electric grid power source into a way to power microscopic chips. But a former professor studying high-energy physics at CERN in Switzerland and the Institute for Advanced Study in Princeton, NJ. spent his considerable and accomplished career solving this problem, moving from theoretical physics to commercialize his breakthrough power conversion methodologies into a business called Vicor.

Founded in 1981, that PhD academic turned billionaire businessman named Patrizio Vinciarelli created Vicor, a business that designs, develops, manufactures and markets modular power components and complete power systems based upon a portfolio of patented technologies. He holds more than 100 patents in electronics conversion technology and in 1990, his company went public (VICR) and now has a market cap over $2 billion.

“I spent the first 10 years of my professional life after graduation doing fundamental research in particle physics, both in Europe, the European Centre for Nuclear Research in Geneva, in the US on the west coast at Stanford and on the East Coast in Princeton. I became somewhat frustrated with the progress in my particular academic field, which had undergone in the past century, dramatic advances, but things were, in fact, slowing down,” says Vinciarelli, who holds more than 100 patents in electronics conversion technology.

He found that the power conversion solutions at the time were primitive and lacked scalability. He converted from Academia to business to investigate ways to achieve much higher power density or the ability to process a lot of power in a small amount of space with less weight and volume. And in the early days of founding Vicor, he came up with ways to perform the power reduction functions at a 10-15 times higher frequency than what was deemed feasible.

It took Vicor some three years to go from theory to its first product in 1984, which provided 25 watts per cubic inch, about 20 times more dense than anything else, at that time. According to Vinciarelli, two Nobel prize winners in Physics provided some of the seed capital to launch Vicor. “And since then, we continue to evolve this key figure so that now we have products that are in the order of 10,000 watts per cubic inch. Relative to where the state of the art was in 1980, there's been a three orders of magnitude increase or 10,000-fold, as we kept improving,” says Vinciarelli.

Vicor’s patented high-performance power modules generated nearly $400 million in sales in 2022, enabling innovation to continue apace in AI, electrifying vehicles, solar energy, automotive, data centers and next generation computing. Headquartered in Andover Massachusetts, the company has over 1,000 employees, with its manufacturing facilities in Andover as well. Vinciarelli is particularly proud that his company has all of its manufacturing facilities in the US.

In fact, Vicor recently celebrated the opening of a new 90,000-square-foot, state-of-the-art power module fabrication facility, also in Andover. The facility was created to support the demand coming from the fast-growing sectors the company serves. According to the company, it’s the world’s first ChiP™ (Converter-housed-in-Package) fabrication facility.

“Vicor has always believed in a US based manufacturing strategy. We always believed that automation and technology should be based in the area where the engineering development takes place, which is pretty close to the foundry itself,” says Vinciarelli.

Vinciarelli says that the near $100 million invested in the new fabrication plant will soon pay off, generating some $1 billion in revenue per year for the company. Even with this investment the company remains cash flow positive, though it remains to be seen if investors will have the patience to put so much capital toward future earnings. Vinciarelli’s answer is that patient investors will be rewarded.

Vinciarelli grew up in Rome, Italy the son of academics, with is father becoming a UN diplomat who travelled to conflict areas around the globe. He was interested in science from an early age and saw the exciting developments happening in physics and pursued his interest to the University of Rome where he went on to earn his PhD. He came to the US for his postdoctoral work spending the next 10 years working on better solutions for power systems that led to his founding of Vicor in 1981. He attributes the success of his early launch days to the encouragement and investments from the physics world and his academic colleagues.

As for the future for Vicor and the 76-year-old Vinciarelli? Might its $2 billion market cap make it a buying target for larger players or Private Equity?

“As you can imagine, investment bankers are circling around. So, we're always interested in talking to them. But frankly, the company culture, I think, is very strong. The market opportunity is huge and timely. We're having a lot of fun, not just myself, but I think the people I deal with in the company are very excited about our prospects. So, we believe we're going to let it ride for the next five or 10 years. And maybe those acquisition opportunities will become even more attractive. Personally, I have a great deal of energy and excitement and I couldn't think of doing anything else,” concludes Vinciarelli.

This article was originally published by Forbes.

Optimizing DC-DC converter stability: AC and transient analysis in simulations of source impedance effects

Learn how to optimize DC-DC converter stability through AC analysis in the frequency-domain and transient analysis in the time-domain

15 technical challenges to consider and conquer when designing a 48V power delivery network

To help better prepare for your 48V migration, consider the following 15 challenges as you embark on your first 48V designs

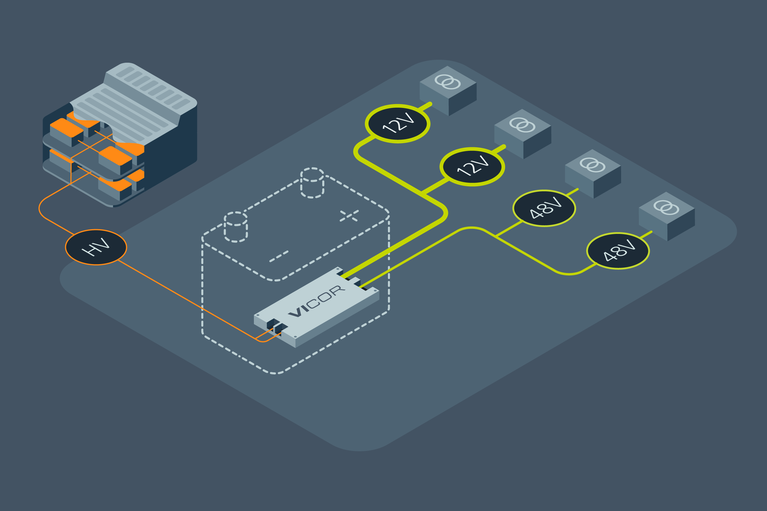

Future-proof automotive high-voltage-to-SELV conversion

Legacy 12V architecture is no longer capable of sustaining the rising electronic loads in automobiles. Learn how power modules hasten the transition to 48V

Power modules simplify creepage and clearance design solutions for electric vehicles

Overmolding is the key to solving arcing issues in 48V automotive power systems