Accelerate your move to a high performance 48V power delivery network

This eBook provides guidance on designing 48V power delivery networks to enhance the performance, efficiency, and reliability of industrial products

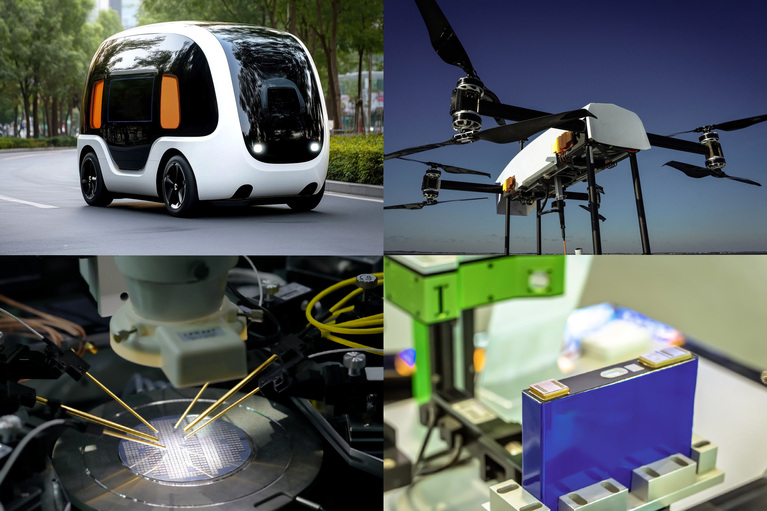

The addition of new sensors like LIDAR (light detection and ranging), together with sophisticated onboard AI processors, has allowed autonomous robots to interact more safely with humans. This manufacturer of security robots needed to integrate the new technologies into an upgraded robot platform that could support the higher processor loads while traveling further after a recharge. This required a larger battery and a smaller and scalable power supply to free up space for it. The key goals were:

The new design employed DCM DC-DC converters for each power rail. These small, highly efficient converters reduced the footprint and weight by 70% compared to the previous brick-based design. It also improved the system efficiency by 30%, reducing power losses and therefore increasing battery range. The DCM’s wide input voltage range allows compatibility with future battery technologies.

Low loss conversion to maximize performance from battery

Free up space by minimizing power supply size

Modular solution to allow future scaling-up of power

Separate DCM DC-DC converters provided each of the four output rails. The converters isolated and regulated the fluctuating battery input voltage. Simple paralleling allows further DCMs to be added in future to meet a higher output power requirement on any rail. To analyze this power chain go to the Vicor Whiteboard online tool.

Isolated regulated

Input: 9 – 420V

Output: 3.3, 5, 12, 13.8, 15, 24, 28, 36, 48V

Power: Up to 1300W

Peak efficiency: 96%

As small as 24.8 x 22.8 x 7.21mm

Accelerate your move to a high performance 48V power delivery network

This eBook provides guidance on designing 48V power delivery networks to enhance the performance, efficiency, and reliability of industrial products

Build better UAVs using modular power

Power Delivery Networks (PDN) based on Vicor high performance power modules enable innovative designs for the next generation of UAV development

UAV Market Trends and Power System Seminar 2025 Taipei, Taiwan

Power modules enable top performance and innovation for today’s advanced UAVs

High-density, high-power modules enable lighter, safer, lower cost tether cables to extend missions

This class of unmanned vehicle is powered and controlled via a tether from a ground-based power source assisting in extended missions