Optimizing DC-DC converter stability: AC and transient analysis in simulations of source impedance effects

Learn how to optimize DC-DC converter stability through AC analysis in the frequency-domain and transient analysis in the time-domain

John McHale, Sr. Editor of Military Embedded Systems, sits down with John Sturm, VP of aerospace and Defense Business Unit, to get his unique perspective on how Vicor power solutions are enabling the next generation of defense platforms and explores what the future holds for the defense industry at large.

By John Sturm, Global Vice President for Aerospace & Defense

Power is a key consideration for modern open architecture initiatives such as the Sensor Open Systems Architecture (SOSA) Technical Standard, says John Sturm, Vice President of Business Development for the Aerospace & Defense business unit of Vicor, when I interviewed him just before Thanksgiving. We also discussed where custom power supplies fit into the defense world and talked about how commercial AI and big data applications are driving innovation and cost reductions in defense power component manufacturing, recruiting engineering talent into the defense market, and what will be a disruptor in military power supplies in the future. Edited excerpts follow.

MIL-EMBEDDED: Please provide a brief description of your responsibility within Vicor and your group’s role within the company.

STURM: I am the global vice president for the Aerospace & Defense business unit of Vicor. I’m also president of the Vicor Power Systems division.

About a year ago Vicor segmented into four distinct business units, Aerospace & Defense being one of them. My team’s roles and responsibilities are understanding the market, defining product needs, conducting business development, and providing customer and technical support for all aerospace, defense, and new space applications globally.

MIL-EMBEDDED: What are the latest design trends/requirements for power supplies in military systems? In other words, what are your military customers looking for?

STURM: From the Vicor perspective, it comes down to two primary topics, the first being standardization and second the AC-to-DC component. For decades Vicor has been a provider of not just power components but also custom power systems and solutions for military applications. Our Vicor Power Systems division, a fully owned subsidiary of Vicor, focuses on these specific power designs. However, these custom solutions or systems are not only time-consuming but also expensive to develop and qualify for something that could be a one-off solution. So, there is big push [in the defense community] to standardize solutions to allow reuse and cut development time and costs. That’s where standardization comes into play. [The Department of Defense (DoD)] have decreased their appetite for specific one-off designs and are pushing for things to be built on more common platforms that will reduce their cost and time to market.

We’ve been producing DC products since the company was founded in 1981. More recently, we’ve been asked to produce modular AC solutions and take advance of our proprietary packaging and switching topology. [However,] with analog engineers aging out in the industry and in the work force, there is an immediate need for high-performance AC component solutions.

These two trends – standardization and AC products – are the hottest items my entire team spends their time focused on.

MIL-EMBEDDED: Future requirements will cover those trends?

STURM: Yes, and they will really come into play with each other from an interoperability standpoint.

MIL-EMBEDDED: Speaking of interoperability, I see that Vicor is a member of the Sensor Open Systems Architecture (SOSA) Consortium. How do power supplies factor into the SOSA Technical Standard?

STURM: SOSA is a strategy that takes advantage of standardization. It outlines a standard form factor for C5ISR [command, control, communications, computers, cyber, intelligence, surveillance, and reconnaissance] systems as a whole. They all require power to operate; by following a specific form factor, the power supply produces specific voltage rails that designers need in the sensor application. What they are trying to do is provide common power requirements in a standard form factor so they can provide plug-and-play options that fit into a standard chassis.

MIL-EMBEDDED: SOSA is an example of a Modular Open Systems Approach (MOSA), a strategy mandated by the DoD in 2019. Are you seeing more requirements related to MOSA and open architectures, not just SOSA?

STURM: Yes, we are seeing more requirements, but that entire landscape is still evolving. SOSA, as it relates to power, mandates the power rails that are used in the application, so it inherently provides a level of standardization. MOSA takes an additional step from a system standpoint to assure compatibility and interoperability in hardware and software development across platforms and vehicles. What started as method to standard size for communications, computing, and ISR applications is now being looked at to enable standard chassis and power requirements across all military systems.

MIL-EMBEDDED: For years power-component designers have said that no matter the application, defense programs always made power an afterthought in the design, that it was not something considered from the ground up in the design. Are open architectures helping to change that practice?

STURM: We used to call it the tailpipe syndrome. When starting a design, everybody looked at what they were going to do from an ASIC [application-specific IC] or processor standpoint or from what the sensor’s prime function would be. Not until the end of the design process did they realize they have to power it. There is nothing we have as human beings that is not powered, so power is very important. What open standards help to do is take the afterthought of power away. They don’t place it at the forefront, but make it a given so people don’t have to think about how they’re going to power a system. It’s already there.

Even though we’ve always had standards – VITA 46, VITA 62, etc. – the evolution never stops because engineers will always say ‘if I had this, I could do this.’ So, as much as the government pushes everyone to standardize, to reduce the negative aspects of going custom there still needs to be a place for something a little different. This is where we can help – because we’re modular and scalable – we offer derivatives that can plug and play into the same form factor or footprint that can specialize it, but not necessarily make it custom. This modular approach can really be a competitive advantage to the customer to ensure long-term power supply for a system.

MIL-EMBEDDED: Do increased MOSA strategies mean less demand for custom solutions as opposed to COTS [commercial off-the-shelf] VPX power supplies, for example?

STURM: MOSA is leading toward a more COTS approach, but there will be always be the need to customize systems. Vicor can really offer the best of both worlds. We can make custom power supplies that are half-moon-shaped, that are octagon-shaped, etc., because the customer only has so much space left for you to fit the power supply. Now we have these chassis systems that have a standard chassis-size form factor like 3U or 6U and have standard power rails specified, so they know they will get certain voltages at certain current levels. It becomes a pluggable form factor for power supplies, cards, sensors, and single-board computers. However, if a system needs a little more power, we could modify the power card and it would still plug into the standard chassis. That’s an important benefit.

MIL-EMBEDDED: VPX has surpassed VME in new designs for sure, but do you still see much demand for VME or CompactPCI power supplies in the military?

STURM: VME and CompactPCI demand has really fallen off. VPX is still strong and growing all the time. We not only support systems based on VITA 46 and VITA 62 standards, but also in many cases customers need something a little different. Our scalable components enable them to get something a little different that can still fit within the standard form factor.

MIL-EMBEDDED: What are the hottest defense application areas for your power supplies? Radar/EW? Unmanned systems? Space? Avionics? C4ISR? Some other area?

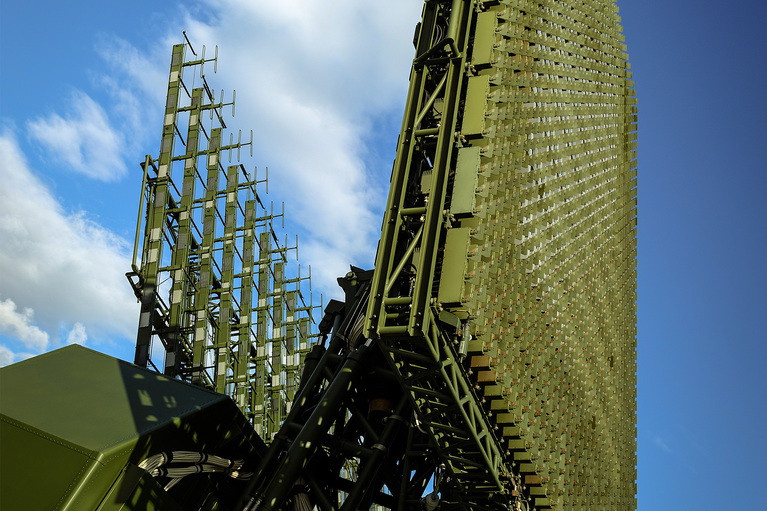

STURM: Those you outlined are the hottest applications for Vicor. When you look at our power density – which not only provides higher power but also [enables] very small form factors – and our pulse-current capability, it means our products are an excellent fit in all those applications. A term that is way overused, but equates well, is SWaP [size, weight, and power]: That’s where our products provide the most value. Our power density means we can provide the highest current available or the most power in the smallest package. This enables high-energy applications like lasers. Also, because of the high current capability and pulse-load capability the advancements made in radar are unbelievable and enabled by these products.

MIL-EMBEDDED: Vicor plays in other, higher-volume markets than defense, such as commercial AI [artificial intelligence]. Do the volumes of these markets help drive component costs down for your military customers? And does innovation in a commercial market impact the defense market and vice versa?

STURM: I’ll answer the questions in reverse and tie them together. In years past, as a company research and development efforts on the defense side really drove technology development and product innovation. That’s where the most demanding needs were coming from, where the aerospace and defense primes were driving their technology and equipment. However, in more recent years the products and packaging we developed specifically have come from data center and AI applications. They’ve really raised the performance bar and my team specifically has been able to take advantage of the products we developed for those other core platforms.

Cost is absolutely a concern for us. As a U.S. manufacturer, we have made and continue to make significant investments in vertical integration, high-speed, high-volume capability to minimize component cost and manufacturing expense. To that end we expanded our manufacturing floor space this year by 45% to accommodate higher demand. That’s been a necessity on the commercial side, specifically in AI and high-performance computing (HPC) data center markets. This has translated over to the aerospace and defense side, enabling us to manufacture those components much less expensively through shared cost and more efficient factory utilization.

Our manufacturing approach is analogous to how semiconductor companies produce chips on a wafer, which we refer to as a panel. As we develop smaller power modules, we can produce more modules on a single panel and reduce the cost per component accordingly. At the same time, the smaller modules have higher power density, so we achieve both lower cost and higher performance.

Then there is the vertical integration play. Years ago, Vicor was very vertically integrated, but advancements that came about in other technologies like in the field-effect transistors (FET) market, made it difficult to remain competitive. Sourcing die and doing wiring, bonding, and packaging in-house was a huge expense. It was difficult to keep up with the large suppliers in that market space. But today we are again investing more in vertical integration to not only control where our products are made but also to control how long it takes to make them. Vertical integration enables us to produce the high volumes we need but more importantly, getting to zero-defect levels. This is necessary to help us better serve high-volume markets like automotive. Operations that were once outsourced will be internal to Vicor in upcoming years because we’re not certain we can achieve the quality levels we demand through outside suppliers.

MIL-EMBEDDED: Trade shows have returned in full and I’ve been to quite a few myself and I still see a trend I saw before the pandemic – more gray-haired folks than not. Does the military electronics industry have a recruitment challenge on its hands in terms of hiring young engineers? How does Vicor recruit engineering talent to its military business?

STURM: This hits home to me because I’m a gray-haired gentleman. We are trying to do what we can to mitigate that. It is hard to compete against companies that are in trendy markets with trendy products and provide lots of lifestyle benefits to young individuals coming out of college. We’re trying to hire interns to work at Vicor while still in college and recruit new graduates to show and introduce them to what we enable around the world based on our technology. I don’t think many young graduates come out of school and look at our industry and say ‘wow it’s really innovative, and I should go there.’ But disruptive innovation is what Vicor is all about. We see that in our power products, and we try to demonstrate that to young candidates and interns so that when they get out of school, they don’t just look to a data center or processor or ASIC company, but see that Vicor could also be a good fit and career opportunity.

MIL-EMBEDDED: Speaking of disruption: Looking forward, what disruptive technology/innovation will be a game-changer in military power electronics?

STURM: The things that I see as the biggest game-changers are high-voltage-related, especially in our market. Right now we’re tied to standards MIL-STD 1275 and MIL-STD 704, which dictates the bus voltage available for the systems, architects, and electronics. Higher voltages are where they are going to get a better efficiency and reduction in I2R [I2R is the power lost that is caused as current moves through wires or cables of a known resistance] losses especially as vehicles – personal and transit – continue along on electrification and hybrid paths. Those benefits allow end users to take advantage of better battery technology, reductions in system weight, and increases in performance and capability by allowing them to take advantage of more state-of-the-art computing devices and systems. That’s where I see our industry moving toward and benefiting from. We have to start thinking about deviating from the historic specs that have been a part of our lives for so many decades, to see what we can do differently to benefit us moving forward.

This article was originally published by Military Embedded Systems.

John Sturm joined Vicor in 1997. He has over 33 years of experience in electrical design engineering, engineering management, business development, sales, and sales management. In his current role he is focused on leading the company’s business in the aerospace and defense market while developing key partnerships with prime contractors in the industry. Prior to Vicor he was with TDK Corp. of America and Grayhill Inc. John holds a B.S. in electrical engineering from the Illinois Institute of Technology and an MBA. in marketing and finance from the Lake Forest (Illinois) Graduate School of Management.

John Sturm, Global Vice President for Aerospace & Defense

Optimizing DC-DC converter stability: AC and transient analysis in simulations of source impedance effects

Learn how to optimize DC-DC converter stability through AC analysis in the frequency-domain and transient analysis in the time-domain

Power under pressure: Meeting the military’s surging energy demands

More capability (power) and compatibility are in demand for military power system designers. Learn how the Vicor SOSA Power Supply solves this problem

Providing well-regulated 48V at over 1kW

Learn how Vicor delivers power at 1kW with efficiency and reduced weight

Reducing I2R losses to enable extended missions

Learn how Vicor delivers high power with efficiency and reduced weight for electronic countermeasures