Optimizing DC-DC converter stability: AC and transient analysis in simulations of source impedance effects

Learn how to optimize DC-DC converter stability through AC analysis in the frequency-domain and transient analysis in the time-domain

By examining factors such as reliability, scalability, size, weight, and power design expertise requirements, we will delineate the differences between design options and distill the benefits of a modular approach to power system design.

When designing a power delivery network (PDN), the decision to use power modules vs discrete power solutions requires careful consideration of design variables. Understanding the advantages of using power modules, particularly high-density modules offered by Vicor, over home-grown discrete solutions is important. By examining factors such as reliability, scalability, size, weight, and power design expertise requirements, we will delineate the differences between design options and distill the benefits of a modular approach to power system design.

Power modules have fewer points of failure because there are fewer design components. Compared to discrete designs, power modules require fewer connections, reducing the likelihood of quality defects during assembly. Moreover, with fewer assembly stages, there is a decreased need for board handling by operators, mitigating the risk of electrostatic discharge (ESD) damage during the manufacturing process. These factors contribute to improved reliability, making power modules a more dependable choice for power system design.

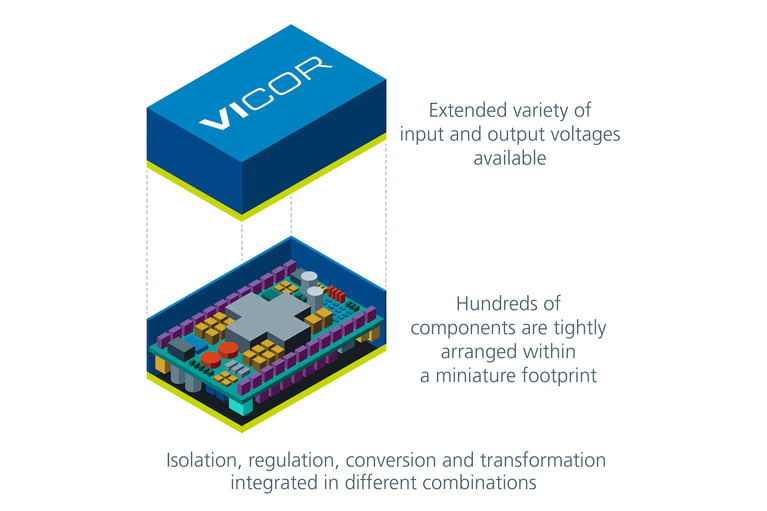

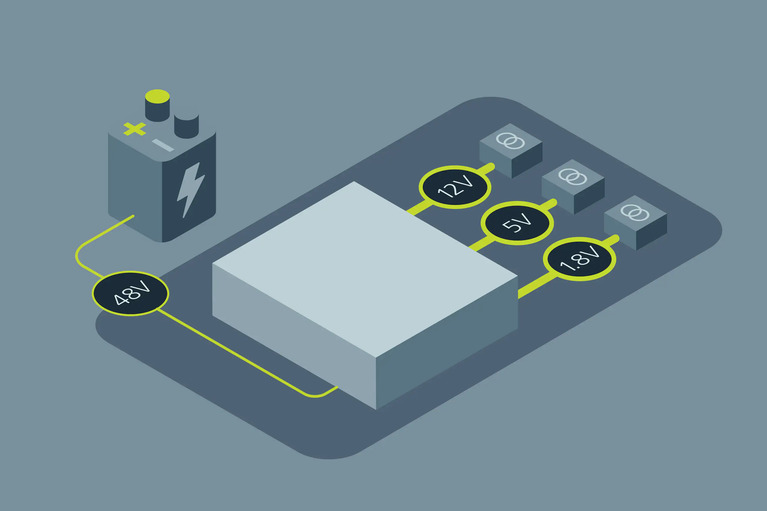

Vicor power modules are small and power dense (Figure 1). Given most power designs must fit into a very confined space, small power modules add flexibility. The compact design offers the ability to scale and accommodate changes in power requirements without costly and time-consuming redesigns. By reusing prequalified modules, designers can avoid additional testing, recertification and sourcing efforts associated with a complete redesign. This flexibility and scalability of power modules enables design changes to be implemented quickly and efficiently, resulting in shorter development cycles and cost savings. Ultimately, this translates into faster time-to-market.

Figure 1: Vicor power modules are small and power dense with an extended variety of available input and output voltages; hundreds of components tightly arranged within a miniature footprint; and isolation, regulation, conversion, and transformation in different combinations.

When evaluating the choice between power modules and discrete designs, it is crucial to consider the entire life cycle of the product. In the case of a discrete design the burden of design, testing and validation falls solely on the in-house power design team. Furthermore, obtaining the necessary certifications from third-party agencies and managing the complex manufacturing and sourcing processes introduces significant risks and potential delays. Any scaling requirements can necessitate a complete redesign, further prolonging the development timeline.

In contrast, using power modules simplifies supply chain logistics and reduces the stress on the organization. These prequalified modules, such as the ones from Vicor, have undergone thorough testing and quality control, ensuring their reliability and compliance. Additionally, as power requirements increase, reusing the same modules allows for seamless scalability, eliminating the need for extensive redesign efforts.

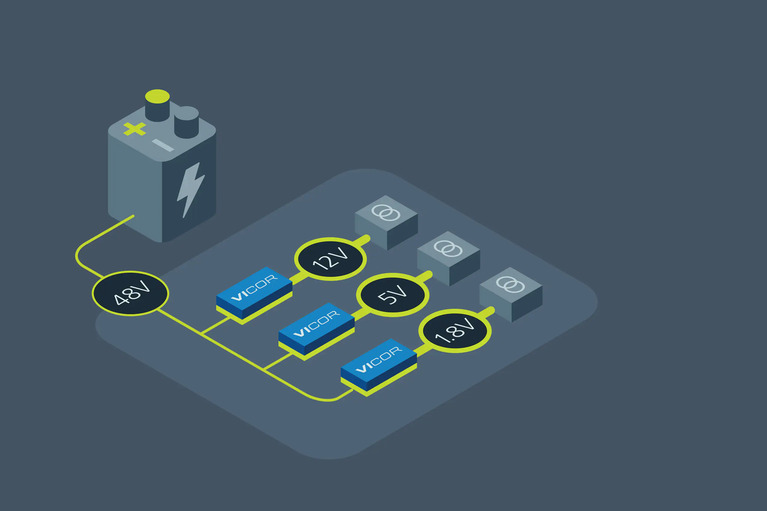

Power modules offer a simpler approach to power system design that requires less expertise. With their miniaturized form factor and high power density, they occupy less physical space, leaving more room for other components on the PCB (Figure 2). The high efficiency of these modules also simplifies thermal management, reducing the complexity of cooling solutions. This simplicity translates into faster and easier design iterations, updates and overall system maintenance.

Figure 2: A simple, modular approach is flexible, easily scalable and requires less technical expertise to optimize a power delivery network.

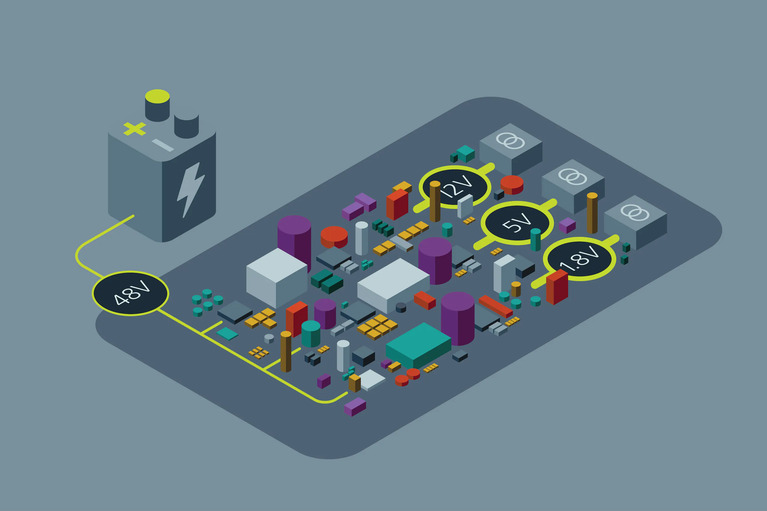

On the other hand, discrete power solutions present a complex landscape that demands extensive expertise, time and effort throughout the design process. These solutions involve the procurement, validation, and integration of many components (Figure 3). Even minor design modifications require a high-touch approach and can disrupt the project schedule and introduce unwanted risk.

Figure 3: Discrete solutions have more components to manage which increases design complexity.

Discrete designs also suffer from inflexibility when it comes to adding more loads or adjusting power and voltage levels (Figure 4). Routing additional voltages consumes valuable space and adds weight to the system due to the requirements of larger boxes and cables. Moreover, these discrete solutions are susceptible to noise and external interference, impacting their overall performance and reliability.

Figure 4: The silver box is a nice plug-and-play solution, but often is large, heavy, and inflexible.

In conclusion, when evaluating power system design options, power modules offer several significant advantages over discrete power solutions. Vicor power modules, with their advanced topologies, miniaturization, and thermally adept packaging, provide superior power density, efficiency and reliability compared to alternative discrete designs or silver-box options.

The use of power modules simplifies the design process, reduces the component count and likelihood of technical design errors, and enables faster time-to-market for new products. Additionally, the modular approach allows for easy scalability and flexibility, eliminating the need for time-consuming redesigns when power requirements change.

With the assurance of prequalified modules, simplified supply chain logistics and the ability to easily reuse modules and quickly scale PDNs, power system designers can focus on innovation and optimization rather than grappling with the complexities of a home-grown discrete solution. By choosing Vicor high-density power modules engineers can achieve efficient, reliable and scalable power delivery networks while saving valuable time and resources to get to market faster.

This article was originally published by Mouser Electronics.

Optimizing DC-DC converter stability: AC and transient analysis in simulations of source impedance effects

Learn how to optimize DC-DC converter stability through AC analysis in the frequency-domain and transient analysis in the time-domain

15 technical challenges to consider and conquer when designing a 48V power delivery network

To help better prepare for your 48V migration, consider the following 15 challenges as you embark on your first 48V designs

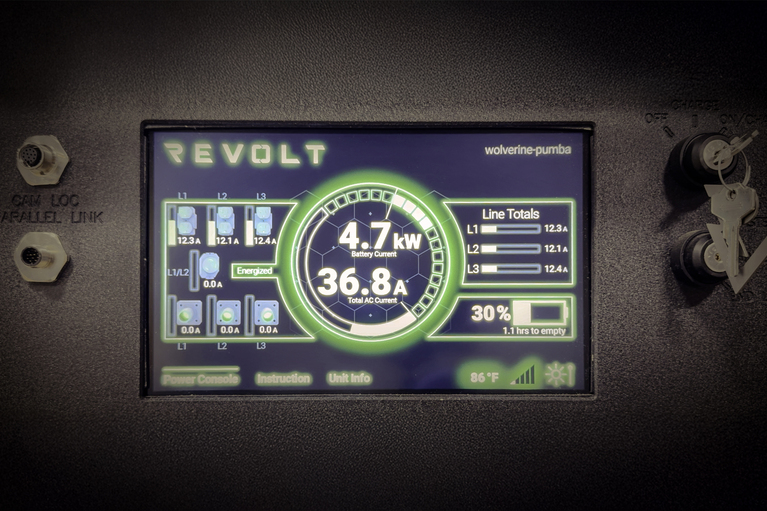

ReVolt – Technical Q&A

ReVolt is cleaning up Hollywood's emission problems today and next will address construction sites, emergency response and events with portable DC power

How ReVolt leverages Vicor technology for carbon-neutral film production

Vicor’s power converters to provide clean, mobile, and always-on electricity