Accelerate your move to a high performance 48V power delivery network

This eBook provides guidance on designing 48V power delivery networks to enhance the performance, efficiency, and reliability of industrial products

Weaving looms take spun cotton yarns and combine them into a woven fabric. Loom manufacturers are looking for ways of reducing the size and cost of their equipment while improving equipment flexibility, allowing end-users to make quick changes to the cloth’s weight, pattern and style. The key goals were:

Typically hold-up and smoothing of the rectified 3-phase AC input is provided by a large bulk capacitor. By following the rectifier with a wide input range DCM DC-DC converter, this hold-up capacitor was completely eliminated, saving both bulk and cost. Stepper motors require the DC supply to source large pulses of current. A DCM can support large capacitive loads at its output and this capacitor reduced the peak current demands on the converter, and thus its size and cost. The capacitor provided power averaging of the high current pulses to the motor with the converter recharging the capacitor continuously between stepper motor load pulses.

Energy consumption and running costs were reduced by the supply’s improved power factor and high efficiency (94%)

Power averaging allowed a smaller (33cm2), lower weight power supply that could easily be integrated into the motor assembly

The DCMs are easily paralleled to provide higher power to meet the demands of larger motor drives

The power source to the loom was a 3-phase 115V AC supply, which was rectified to provide 300V DC. By following the rectifier with a wide input range DCM DC-DC converter, the hold-up capacitor was completely eliminated. To analyze this power chain, go to Vicor Whiteboard online tool.

Isolated regulated

Input: 9 – 420V

Output: 3.3, 5, 12, 13.8, 15, 24, 28, 36, 48V

Power: Up to 1300W

Peak efficiency: 96%

As small as 24.8 x 22.8 x 7.21mm

Accelerate your move to a high performance 48V power delivery network

This eBook provides guidance on designing 48V power delivery networks to enhance the performance, efficiency, and reliability of industrial products

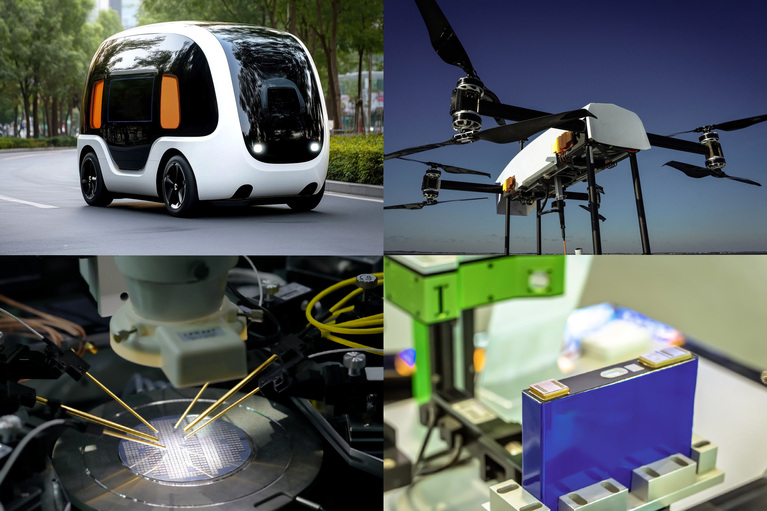

Build better UAVs using modular power

Power Delivery Networks (PDN) based on Vicor high performance power modules enable innovative designs for the next generation of UAV development

UAV Market Trends and Power System Seminar 2025 Taipei, Taiwan

Power modules enable top performance and innovation for today’s advanced UAVs

High-density, high-power modules enable lighter, safer, lower cost tether cables to extend missions

This class of unmanned vehicle is powered and controlled via a tether from a ground-based power source assisting in extended missions