Automotive Event

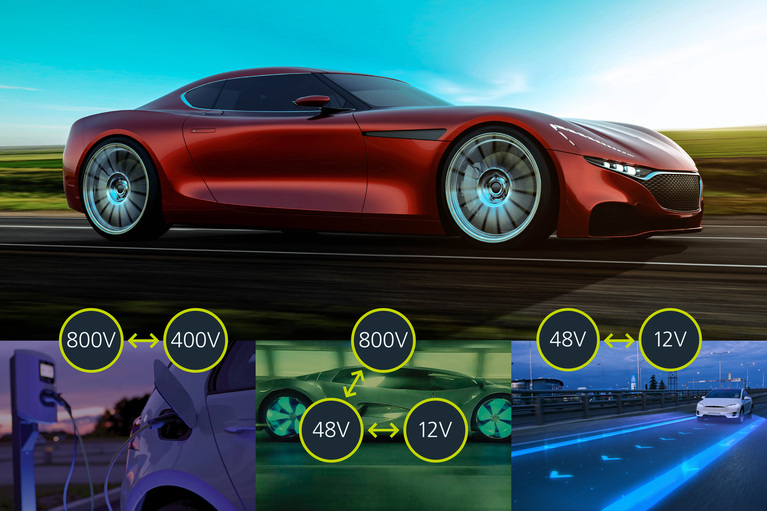

Vicor offers solutions for 48V zonal architectures and high voltage conversion

Solving automotive electrification challenges with the highest efficiency and highest power density power modules

North America’s largest technical mobility event, WCX™, brings together the brightest minds in mobility for critical conversations. The WCX™ World Congress Experience is where the engineering community convenes on mobility’s biggest hurdles from mass deployment of electric vehicles to developmental timelines for autonomous vehicles to understating of global supply chain constraints impacting the automotive industry. World Congress Experience is an event of the Society of Automotive Engineers (SAE).

Vicor presented at five WCX sessions

Eliminating the high voltage pre-charge with existing hardware in BEV

Presented by Patrick Kowalyk, Automotive Principal Field Applications Engineer, NA

Any high-voltage bus needs to have a pre-charge circuit to reduce the current flow over a period of time, called the dv/dt, to protect the electronic devices in a battery electric vehicle. The challenge with a traditional solution to this age-long problem is that the pre-charge resistor charge time is inversely proportional to the power dissipation.

A better approach is taking the power components in the battery electric vehicle and reusing them to charge the high voltage bus from a low-voltage source. Using power modules the regulator can be used in reverse, regulating the voltage and current.

Patrick Kowalyk has been providing automotive power systems for over 6 years, but has been practicing engineer for decades. Patrick’s deep technical knowledge has been instrumental in growing the Vicor automotive business. His technical mastery of electrical engineering as related to power modules, topologies and architectures is second to none. Kowalyk has been a catalyst for helping design compact, efficient power systems for OEMs and Tier One customers. He holds a BS in Electrical Engineering from the Illinois Institute of Technology.

The uncertain future of aftermarket loads in a 48V world

Presented by David McChesney, Strategic Account Manager, North America

High-power loads heavily tax the 12V system in current heavy-duty and super-duty passenger trucks, and these loads are key for the consumer to effectively use their vehicle. Converting these loads to 48V creates a diffusion of responsibility between OEMs and aftermarket suppliers. Who owns this conversion? As these trucks make the switch to a 48V architecture, how will the aftermarket suppliers respond? What should you be thinking about now to make the transition easier in the near future? What is the best approach now that can future-proof the ongoing transition to 48V? Flexible, scalable, and power-dense DC-DC converter modules are a key to a smooth migration for both the OEMs and aftermarket players.

Dave McChesney is a Strategic Account Manager, selling DC-DC converter modules to OEMs and Tier One customers. He has spent his career selling hardware, systems, and engineering services into the automotive engineering industry. With a deep passion for all things EV, he offers a deep technical understanding of power delivery networks and best practices for optimizing xEV platforms. Dave earned his MBA from Walsh University before and studied Electrical Engineering at Kettering University.

Migrating to 48V with high efficiency, power density and efficient system cost

Presented by Patrick Wadden, Vice President Automotive Business Unit

Learn the most practical way to convert 800V to 48V using the most power dense converters on the planet. We will demonstrate how Vicor’s fixed ratio bus converter modules can solve the complex challenges of converting high voltage to SELV in a small, highly efficient modular form. Gain knowledge of how to convert high-power automotive loads like active suspension, steer by wire, and brake by wire to 48V or how to convert the entire power delivery network as Tesla has done, but better. Discover the highest efficiency, highest power density, most advanced power solutions in the automotive industry.

Patrick Wadden joined Vicor in 2018 to head up the automotive Business Unit and to drive a new end market segment for Vicor. His experience in the semiconductor industry was spread across automotive, industrial, consumer and aerospace industries with a concentration in power electronics. Patrick previously held leadership roles in sales, marketing, product line and business unit management at Intersil, Altera, ADI and Integrated Device Technology. Patrick holds a BSBA in Management at Northeastern University and lives in NH with his wife and children.

Achieving EM conducted emission compliance for high voltage conversion with switching frequency above 1.3MHz

Presented by Nicola Rosano, Sr. Strategic FA/System Engineer

Fixing electromagnetic interference (EMI) in systems employing high-frequency DC-DC converters poses a critical challenge due to the intrinsic nature of these converters. High-frequency operation and compact layouts, while beneficial for compact designs and efficiency, intensifies EMI concerns. The rapid switching of currents in these converters generates harmonics that can propagate through the circuit and radiate as electromagnetic waves.

Mitigating EMI requires sophisticated filtering and shielding strategies, adding complexity to the design and increasing costs. Achieving effective EMI suppression without compromising the converter's performance requires a delicate balance, as aggressive filtering may hinder efficiency. Intricate trade-offs are required to develop a robust systems that meet stringent EMI standards in the presence of high-frequency DC-DC converters.

Nicola Rosano joined Vicor in 2022 as Senior Strategic Application & System Engineer, EMEA, offering technical support and consulting for automotive power systems. Prior to Vicor he worked in the military, defense and space sectors at Thales Alenia Space and Airbus Defense and Space, as well as in the automotive sector at BorgWarner and Stellantis as a Senior HW Power System Engineer. He has several patents and is cultivating an analog/power electronics educational YouTube channel. His current research focus include power electronics, circuits and systems, electronic instrumentation, and engineering education. Rosano received his B.S. degree in 2010 and his M.S. degree cum laude in 2013 in electrical engineering.

Designing 48V zonal architecture that keeps the high voltage inside the BEV battery pack

Presented by YK Choi, Sr. Field Application Engineer, Vicor, APAC

YoungJae Kang, Chief Engineer, INFAC Corporation

The future BEV systems will be required lots of heavy loads and safety system with 12V legacy power. Generally BEV has double layer power structure, but when OEMs adapt zonal architecture the system requires triple layer power with additional 48V. The most of DC-DC converters in vehicle have standard power rate, it's simple to increase power demand by add one or two dc-dc converters in vehicle, it’s possible but how we can deal the volume of dc-dc converters and wire harness in system.

YK Choi is Senior Field Application Engineer at Vicor, APAC. YK has over 26 years of experience in power electronics, power modules (IGBT, SiC), discrete switches and semiconductors. He has expertise in vehicle electrification based on traction inverter systems. Mr. Choi has held positions as an R&D engineer and as a field applications engineer in semiconductor test equipment and has also worked at Infineon Technologies. He has MS in Power Electronics and BS in Electrical Engineering from Konkuk University in Korea.

Youngjae Kang has over 20 years of experience in the structural and automotive industry. He is a Chief Engineer at Infac, based in their Michigan office. Youngjae’s mastery and expertise lies in CAE analysis and structural analysis. Dr. Kang has earned a Ph.D. in Structural Engineering from University of Michigan, and an M.E. and B.E. in Civil Engineering from Kyunghee University in Korea.

Vicor had several different power systems in our booth to show the difference power modules make when designing a power system.

Fast charging system – Using the NBM9280, we can design a DC-DC converter sized less than 3 liters to provide over 150kW to facilitate fast charging between 800V and 400V systems.

800V-48V-12V converter – This unit uses the BCM6135 and DCM3735 to provide 2 channels of 2kW (total of 4kW) power from the HV battery to the 12V local loads. This very compact design highlights how to provide 4kW of SELV power from only 1 liter of volume in the vehicle.

Related content

Automotive solutions: Converting the high‑voltage xEV battery to 48V or 12V

Article: 48V systems: What you need to know as automakers say goodbye to 12V

Podcast: The future of long-haul trucking is accelerating autonomously on a freeway near you

White paper: High-bandwidth power modules quell the disruption of high-voltage line ripple rejection

eBook: Accelerate vehicle electrification with the smallest, lightest power modules

About WCX™

As North America’s largest technical mobility event, WCX brings together the brightest minds in mobility for critical conversations. The WCX™ World Congress Experience is where the engineering community convenes on mobility’s biggest hurdles from mass deployment of electric vehicles to developmental timelines for autonomous vehicles to understating of global supply chain constraints impacting the automotive industry. World Congress Experience is an event of the Society of Automotive Engineers (SAE).