As Kodiak Robotics integrates autonomous technology into commercial trucking fleets,challenges to be met include the incorporation of sensors to ‘see’ a truck’s environment, and, not least, an uncompromising power system design that needs to be reliable, efficient, and that has the ability to perform in-system health monitoring.

Commercial trucking is the backbone of the US economy. That has never been more evident than in the past few years, as Covid-19-related supply chain disruptions gripped the country. At the same time, it’s becoming harder and harder to find people who want to drive trucks. The average American truck driver is about 48 years old and for long-haul truckers, the average age is even higher, which may help to explain why there was a shortage of 80,000 drivers in the US last year, according to the American Trucking Association.

Many industry analysts believe that long-haul commercial trucking is likely to be the first major use case of autonomous vehicle technology, as highway driving is a less complicated problem to solve, compared to the many nuances of negotiating secondary roads and city streets.

Additionally, from an economic standpoint, the trucking industry can benefit more from vehicle autonomy. The cost of an autonomous driving system is more easily amortized in a truck that operates for between one million and two million miles. Plus, the average human-driven truck is only used for 7.5 hours a day, due to hours-of-service limitations. An autonomous truck can double or even triple truck utilization, only stopping to refuel, receive, and pick up new loads.

Kodiak Robotics targets long-haul trucking autonomy

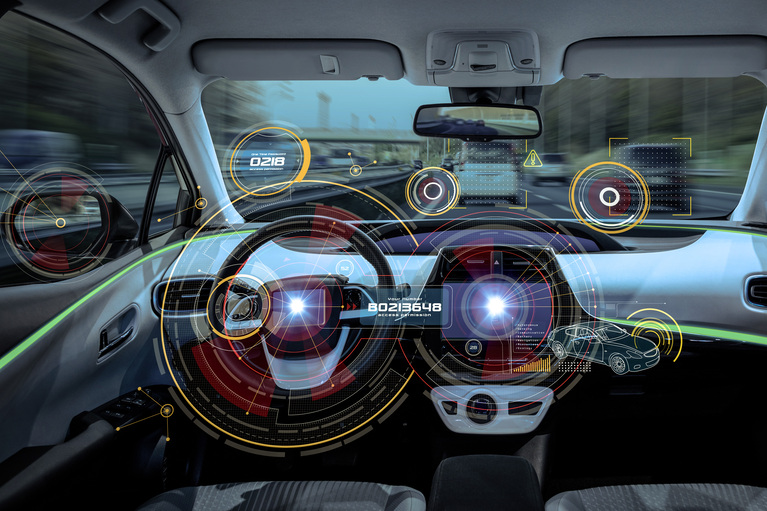

Against that backdrop, Kodiak Robotics was launched in 2018 with a focus of developing autonomous technology for the long-haul environment that can be integrated into carriers’ fleets. Kodiak’s autonomous solution, the kodiakDriver, includes a modular hardware system, known as SensorPods, that integrate the majority of sensors needed to ‘see’ its environment using the truck’s traditional mirror-mount points. The pods’ modular design allows them to be swapped on and off within minutes, which maximizes fleet uptime without the need for specially-trained technicians to install the devices and recalibrate the sensor network.

Since launching its operations hub just south of Dallas, Texas, in 2019, Kodiak has been focusing on safely developing a system that can handle the demanding long-haul environment. This year alone, Kodiak has completed multiple pilots with some of the biggest names in freight, including four uninterrupted round trips from Dallas to Atlanta, with the kodiakDriver continuously operating. Since August 2022, Kodiak has been making autonomous freight deliveries in Texas for home goods retailer IKEA, operating seven days a week between a distribution center in Baytown and the IKEA Store in Frisco.

“The Kodiak team represents some of the most experienced people in the autonomous vehicle industry,” said Don Burnette, the company’s Founder and CEO. “This has allowed us to take the most direct path to success, versus the trial-and-error approach that was common when the industry was starting.”

Vicor power and sensors solutions

"Kodiak quickly identified three areas in an AV trucking environment where the power system design needs to be uncompromising: reliability, efficiency and the ability to perform in-system health monitoring."

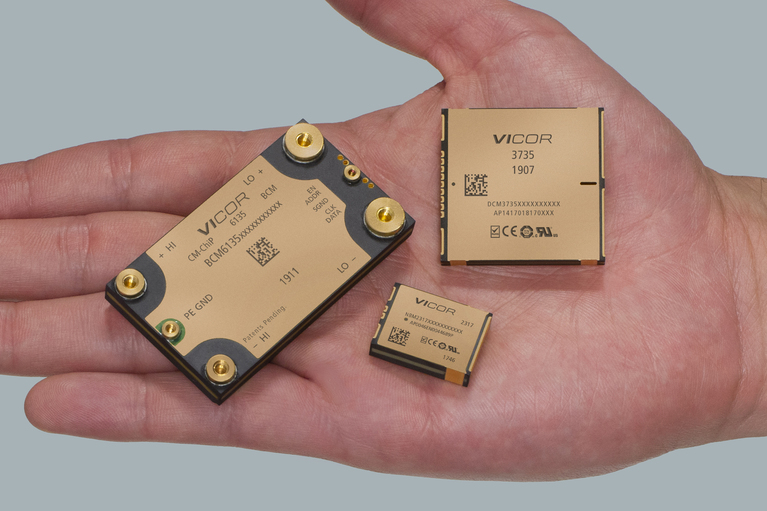

These requirements are what drew Kodiak to partner with Vicor Corporation’s custom design subsidiary, Vicor Power Systems (Vicor). This group designs high-density, high-performance power systems utilizing Vicor’s power modules, that are ideal for autonomous vehicle systems.

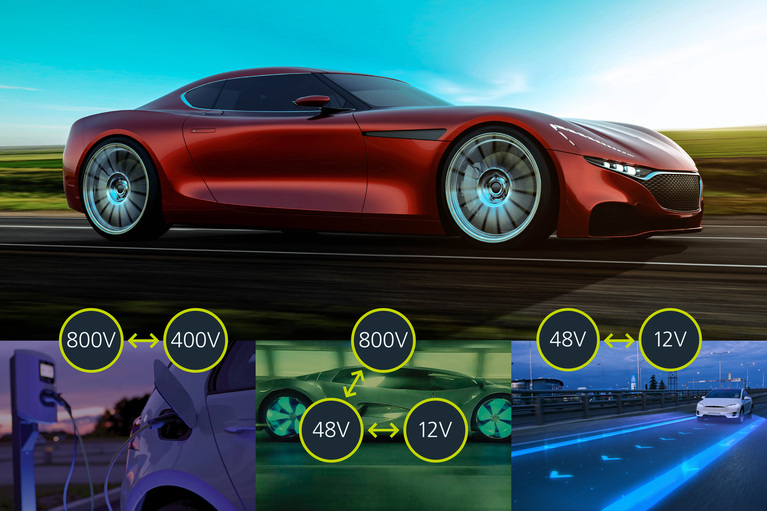

The Kodiak power system utilizes several Vicor power modules to support its sensor needs that require 12, 24, and 48V power supply buses. These include the Vicor NBM6123, BCM6123, PRMs™ and VTMs™. All of the power modules deliver reliable, highly efficient power conversion in very small packages.

"Vicor also provided design support to enable a controllable output feature to every component in the system, and to optimize component health by monitoring the voltage and current on all Kodiak sensors."

The Kodiak platform includes four basic buses that must be directed to specific sensors, actuators and processors. Each output is monitored and individually controlled through a proprietary CAN bus.

Vicor additionally provides battery charging for a 48V system when the truck is garaged and plugged in. The AC shore power system maintains the battery charge level when the engine is not running, allowing maintenance technicians and engineers to use the vehicle indoors. By using a Vicor 48V system on the truck, Kodiak is able to reduce the size of the cabling, saving weight and space, and enabling the vehicle for high-power applications.

Radically changing the future for commercial transportation and truckers

Commercial transportation is underappreciated, yet is indispensable to global economic stability. Today, Kodiak stands ready to revolutionize this industry with autonomous transportation that will enable more reliable and efficient trucking.